When it comes to packaging and end-of-line operations, the wrapping machine is one of the most strategic technologies for ensuring efficiency, continuity, and safety. Its presence in a company can make the difference between optimized logistics and a costly waste of time and materials.

With increasing volumes, shipments, and even increased precision requirements, pallet and goods packaging can no longer be a weak point in the production process. Automating the end-of-line process not only saves time, but also reduces waste, ensures consistent packaging quality, and increases operator safety.

The difference between semi-automatic and automatic wrapping machines

A stretch wrapper is a machine designed to apply stretch film around pallets of products, with the aim of stabilizing and protecting them during transport or storage.

It ensures uniform, safe, and adequately compressed packaging, improving logistics quality and limiting the risk of damage. In other words, avoid the risk of losing goods during transport, eliminating the risk of goods falling and being damaged.

Today, wrapping machines are available in many variants and can be integrated into manual or fully automated workflows. The most advanced models fall into two broad categories: semi-automatic and automatic wrapping machines.

Semi-automatic wrapping machine: for medium volumes and flexibility

Semi-automatic wrapping machines require operator intervention to position the load and start the cycle. They are ideal for medium-to-low production runs or for companies that work with variable batches and require operational flexibility. They offer an excellent balance between performance and initial investment.

Automatic wrapping machine: for continuous production lines

Automatic wrapping machines, on the other hand, are designed to be fully integrated into a production line. They allow pallet loading and wrapping without human intervention, reducing downtime and increasing productivity.

When to Switch to an Automatic Wrapping Machine: Signs You Shouldn't Ignore

Understanding the right time to invest in an automatic wrapping machine is crucial to avoiding bottlenecks, inefficiencies, and waste. But what are the indicators that suggest the transition is now necessary?

Volumes are high and constant

If numerous and consistent pallets need to be wrapped daily, a semi-automatic machine can become a limitation. This is because manual operations slow down the flow and require more time and resources.

Uniform winding standards are needed

With an automatic machine, every pallet is packaged identically. This is essential for those who work with customers who require quality and consistency, or for those who ship in large quantities.

There is a need to reduce time and increase productivity

An automatic wrapping machine eliminates downtime between cycles and can be integrated into the line. This allows for high production rates and reduced labor costs.

The company is integrating Industry 4.0 solutions

If your organization is embarking on a digital transformation, an automated machine with remote control, data collection, and reporting capabilities can become an active part of your transformation.

Greater safety or ergonomics

As volumes increase, the operational load on operators increases. Automation also improves workplace safety and prevents injuries and fatigue.

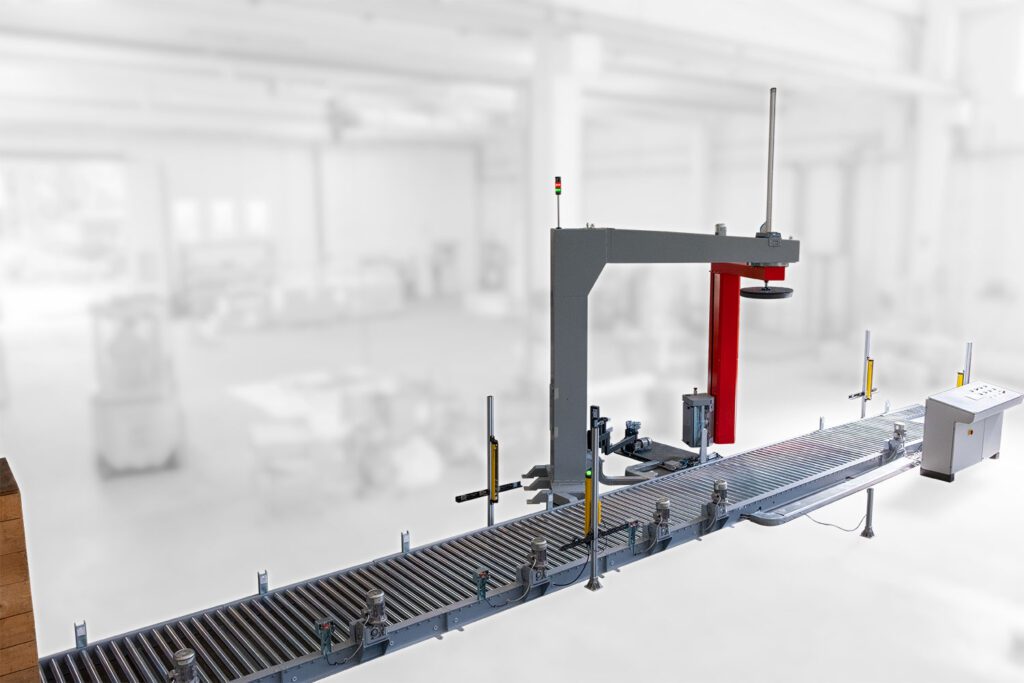

Rotax S5300: the automatic wrapping machine for integrated lines

A concrete example of automatic wrapping machine is the Rotax S5300. This is a rotating arm wrapping machine designed to integrate into automatic lines, with motorized pre-stretch up to 300% (400% in the Dual Motor version), touch screen panel and automatic film clamping-cutting system.

It can wrap pallets up to 1,200 x 1,200 mm (or up to 2,800 x 1,200 mm in the XL version) with detected heights of up to 3,000 mm. The arm can rotate from 4 to 15 rpm thanks to the inverter, while the carriage speed is customizable. It also features a fall arrest system, inverters for all movements, and a robust structure.

Spinny S2300, for total end-of-line automation

There Spinny S2300 is an automatic wrapping machine designed to be integrated into high-productivity packaging lines.

Thanks to the motorized pre-stretch system, it ensures efficient use of the stretch film and allows you to work even with light or unstable loads. It is available with single- or dual-motor pre-stretch, with film stretch up to 300% or 400%, depending on the configuration.

Key technical features include photocell-based pallet height detection, adjustable table and reel carriage speed, automatic film clamping and cutting, a touchscreen control panel, and compatibility with automated lines. It boasts a capacity of up to 2,000 kg.

Why choosing an automatic wrapping machine makes a difference

There comes a time in every company's growth journey when a semi-automatic wrapping machine is no longer sufficient. When volumes increase, lead times become tight, and the demand for high standards becomes the norm, switching to an automatic wrapping machine isn't just convenient: it's necessary.

Effe3Ti's automatic wrapping machines are the perfect solution to these needs. Reliable, safe, and easily integrated into the most advanced processes, they're designed for those who want to make packaging their strength. Choosing an automatic model means investing in continuity, efficiency, and quality throughout the entire logistics chain.