For AUTOMATIC LINES of packaging

TAILORED FOR YOUR BUSINESS

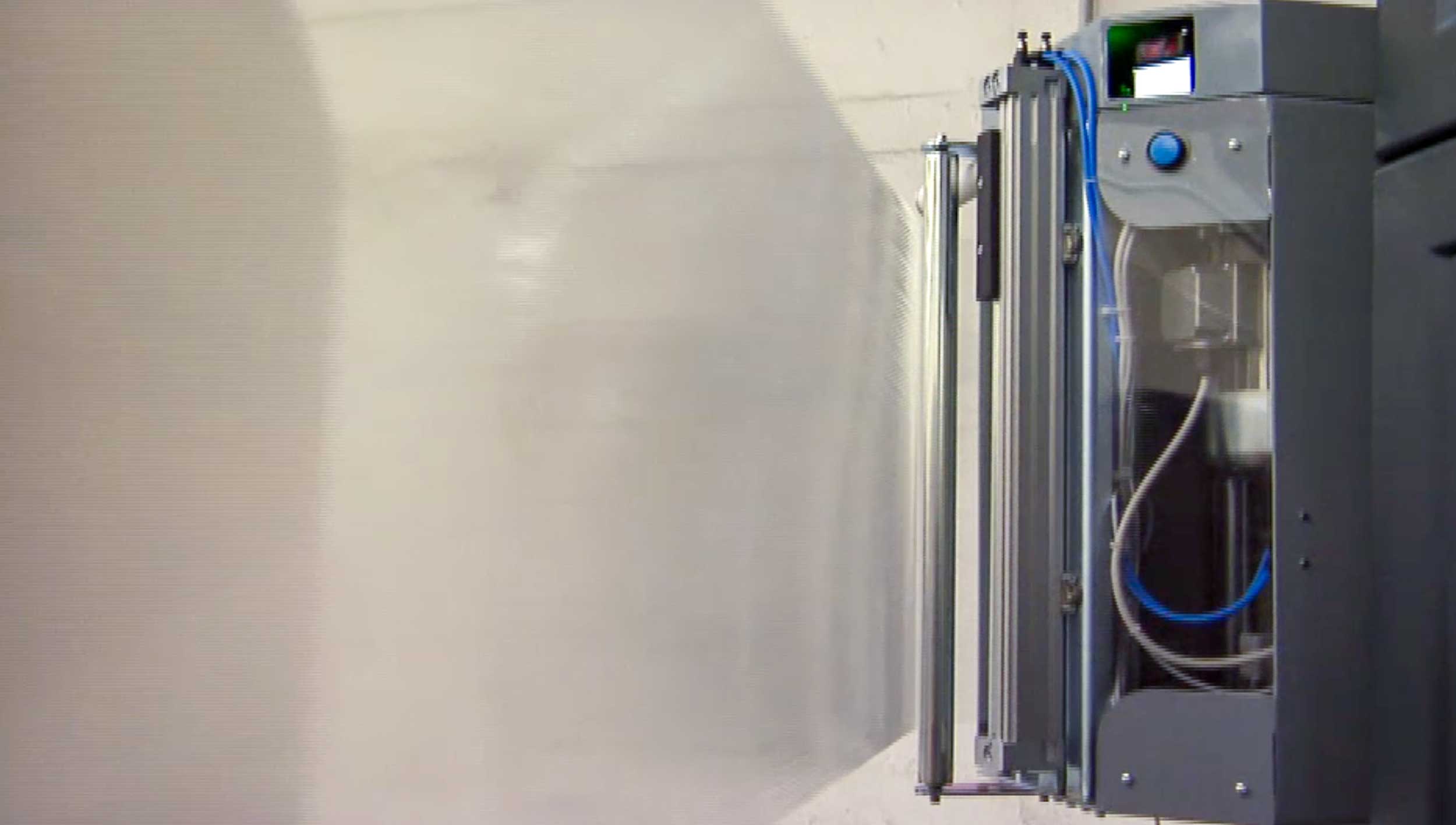

Reel holder with MOTORIZED PRESTRETCH with 1 or 2 motors.

Separate control panel with TOUCH-SCREEN panel

Adjustable arm, trolley and roller speed

AUTOMATIC film clamping and cutting system

Winding height on request

0

Standard winding height

0

Up to three years warranty

0

Perfect for packaging line automation

Automatic film release and cutting clamp

ON REQUEST

Hot film welding

Motorized or pneumatic press

Double motorized pre-stretch

DESIGNED AND MADE BY EFFE3TI

Fully automatic rotating arm pallet wrapper, perfect for packing lines.

Rotating arm wrappers have higher productivity (pallets wrapped per hour) than rotating table wrappers.

TECHNICAL SPECIFICATIONS

- Equipped with motorized pre-stretch which allows significant savings in film used: up to 300% in the standard version and up to 400% in the “Dual motor” version.

- The machine has 10 password protected programs with touch-screen control panel.

- The standard model is designed for wrapping, with stretch film, pallets with dimensions up to 1200 x 1200 mm with unlimited load capacity.

- Standard machine pallet height h=2100mm detected by photocell; special heights up to 3000 mm on request

- The rotation speed of the arm is regulated by an inverter (rotation adjustable from 4 to 15 rpm)

- Sensor controlled arm stop position

- Customizable reel carriage speed regulated by inverter

- Siemens Touch Screen Control Panel

- Anti-fall system of the reel trolley